Coil processing is the transformation of Steel Coil into variety of shapes and sizes.

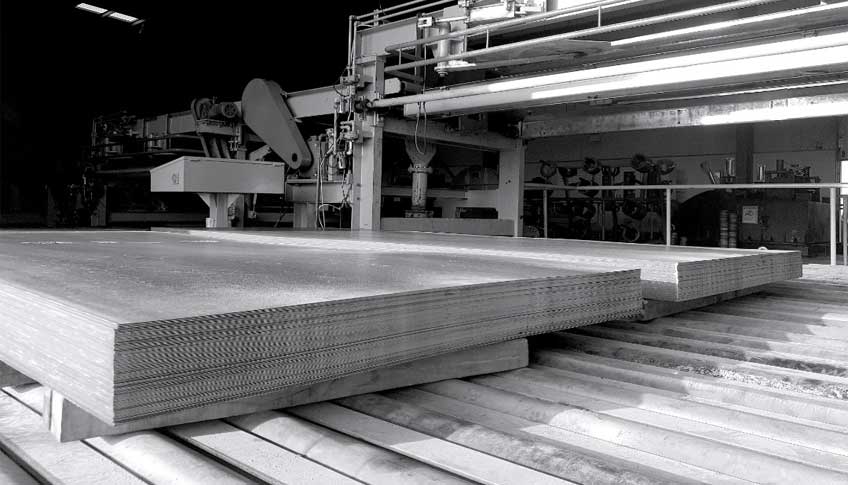

Two main services of coil processing are Cut to length (CTL) that final products are either sheet or plates and Cut to Width (Slitting) that the final product is Silted Coils.

Coil Processing other services

Other sub-services of coil processing due to similarity of machines/equipment are as follow

- - Coil shape standardization on deformed Steel Coils due to Logistic and warehousing mistakes

- - Coil Stretching or Straightening for wavy surfaces

- - Coil Edging of rusted or deformed edges

Did you know many things around us are result of this process?

Air Planes, Ships and yachts, home appliances, cars, water tankers and even in buildings like pre-engineered buildings or cable trays to organize buildings electricity are all built with steel sheets and plates which is final outcome of steel coil processing.

FISTCO offers two mentioned main services to all above industries to clients around the world

Discover more (direct to coil processing service page)

coil processing equipment and coil slitter machine

It is interesting to note there are only two types of machines for all above services but with a single critical difference and that's the cutting blades which are vertical cutting blades for Slitting Machine and Horizontal cutting blades for cut to length machine.

There might be many other small differences which has not much effect to actual process function.

how are steel coils made?

To simply express the feel and like of the machines, process starts by putting up a coil on coil holder which can handle various size based on Machine capabilities.

Coil Holder is responsible to hold up the coil up to puller level in order to pull the coil into a deep whole to backlog a load for leveler.

Leveler stretch and flatten the coil to void the wave and pass it to one of either vertical or horizontal blades in order to process cut to length or slitting process.

There's variety of scrap collected for different machines and finally a coil gathered for Slitting Machine and offload bay for CTL machine for packing.

Machine manufacturers produce variety of machines based on market needs; some machines might have two levelers.