You are about to read one of the Harry Jiang’s speeches about steel environmental impacts in which carbon emission during the making process of steel and its envi-ronmental impacts are discussed.

Note: keep reading to find out “how to decrease greenhouse gas emissions from iron and steel production by alternative methods of steel processing.”

Harry Jiang is an advanced software developer, consultant and entrepreneur in Son Jose, CA. Not only he’s studied at the university of Stanford and California Berkeley, bit also he is the founder of Tripcipe and employee at Kitchip.

The importance co2 emissions from steel production

Steel can be seen in almost every aspects of our lifestyle such as building construc-tions, industrial machines, cookery, automobile vehicle manufacturing and even bi-cycles. Therefore it is crystal clear that by producing different kinds of steel such as Steel plate, steel sheet, steel coil, sustainable steel and other many types there would be a great amount of carbon emissions.

Have you ever taught how much co2 is produced per ton of stainless steel? generally, half of stainless steel scrap (ISSF, 2013) get sued to produce one ton of stainless steel. therefore co2 emissions would be less than 20% per MTof stainless steel.

As an illustration In 2012, 22.8 million tons of carbon was released to the atmos-phere by only making iron and steel, which is equivalent to the annually carbon in-take of 7355 adult trees! Is there possibly a solution to it?

alternative methods of steel making to reduce carbon foot-print in steel industry

1. Improving the design of the steel and co2 system

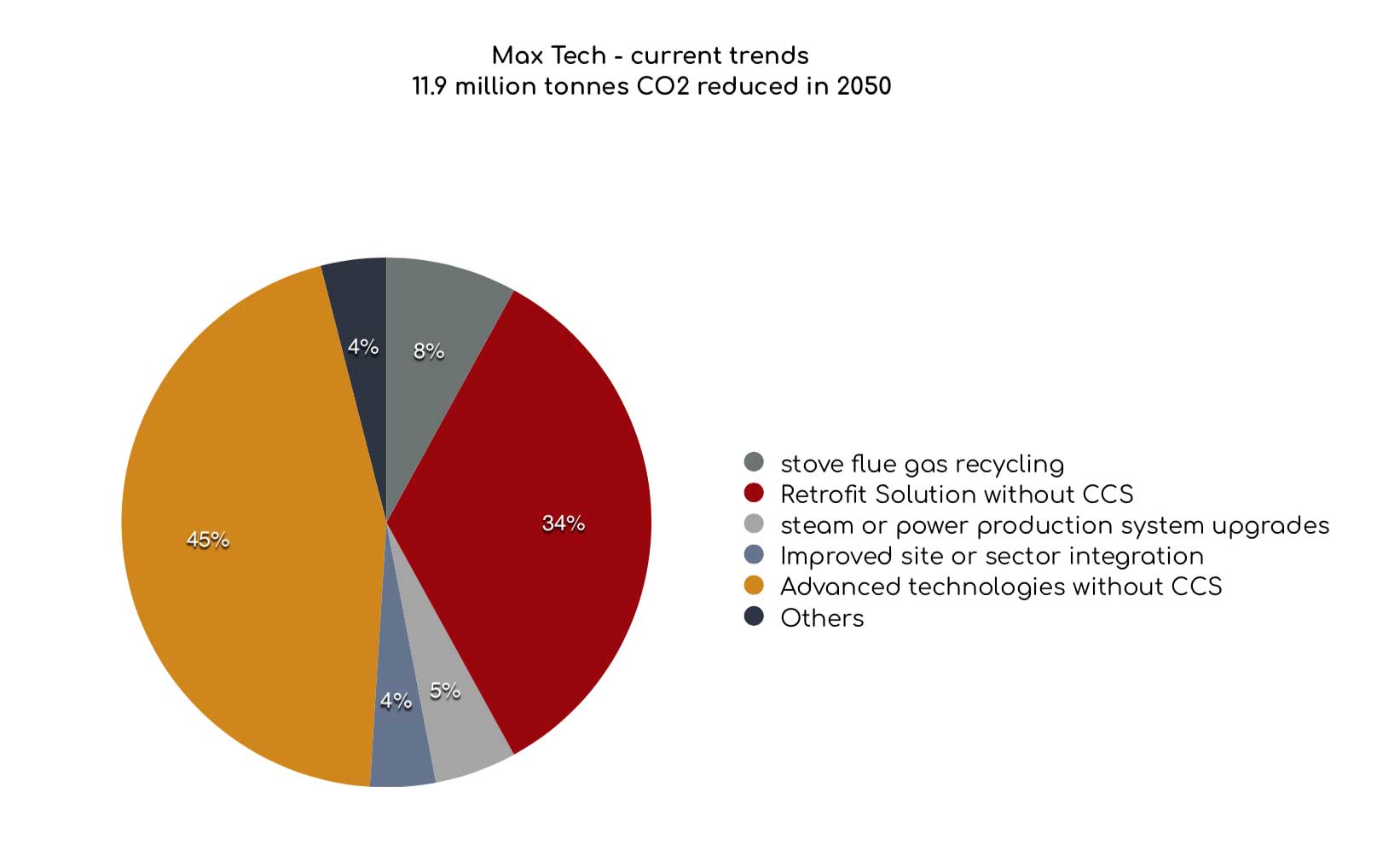

The best scenario is expected to reduce 11.9 million tones carbon emission in uk by 2050. By a simple calculation, from now to 2050 there is 31 years and im-provements can only recover carbon emission impacts by half of the amount that it was released in 2012!

2. Using Hisarna system to replace the traditional systems

Hisarna system has a typical characteristic of removing extra steps in making steel.

- Allows the direct use of raw coal and iron ore, it removes the two extra puri-fying process mentioned before, therefore reduces the carbon emission sig-nificantly.

- Hisarna system also has it’s own carbon capture machine, which extract co2 from purifying process and store it underground, which stops co2 escape to atmosphere and increases greenhouse effect also it helps slowing climate change.

- There was a Hisarna plant built in Australia in 2009, but it was shut down due to high operation costs. Currently, a Hisarna pilot plant was built in Germany and it is still under testing campaign period, the time of its commercial operation time is unknown.

3. Other short-term improvements are replied on redesign and rebuild of tra-ditional systems. Which only contribute to very little co2 emission reduc-tion.

There is no doubt that human can’t live without earth metals, but that amount of co2 in the atmosphere is a very big

danger to climate and of course people’s lives. so here comes a question, is it possible to continue the same way of

making steel with-out killing our planet?

We in Fistco team are going to expand this article. Stay tuned.